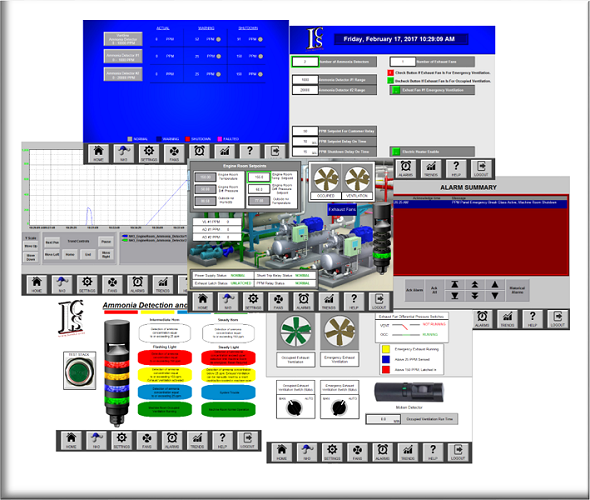

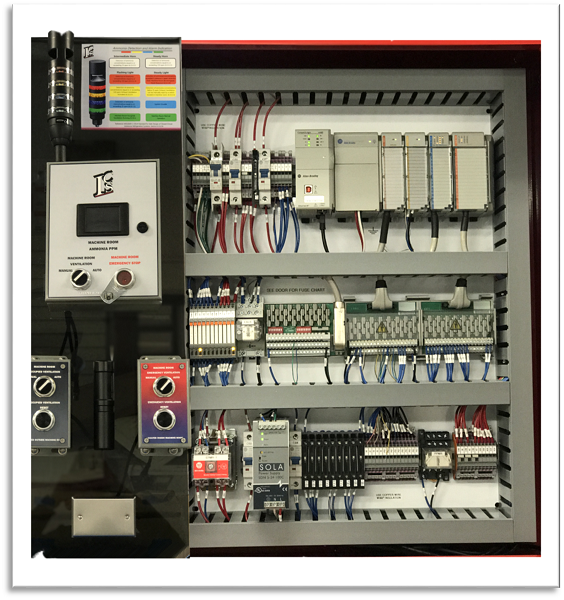

Each system comes with a Main Panel configured for each customer specific engineering needs. The programmable logic controller can be specified as Allen-Bradley, Wago, Siemens, or other manufacturers. The system will utilize a 10-inch or larger touchscreen as an operator interface for user interaction with the system. The system can be configured for multiple ammonia detectors located in the machine room. A configuration will allow personnel to span the ammonia detectors range from the operator interface. Each ammonia detector power and analog signal is monitored to alert personnel of an issues with ammonia detectors. The panel will have a shunt trip relay that can be configured to shutdown multiple compressors and other circuits based on engineering needs. Each panel has a configurable PPM Relay that can be set to trigger at any ppm concentration sensed for monitoring to other control or security systems. There is contact that can be monitored to alert personnel in case of a power failure of the system. Each system will have two remote mounted control stations for ventilation control. A tailored PPM panel can be installed to allow for remote monitoring of ammonia concertation and ventilation control at a machine room door. Motion Detectors for each machine room entrance door to allow for occupied ventilation to be turned on. Engine Room Temperature sensor to allow for temperature control of machine room.

PPM Simulate:

0